904L RVS coiled buizen leveransiers yn Sina

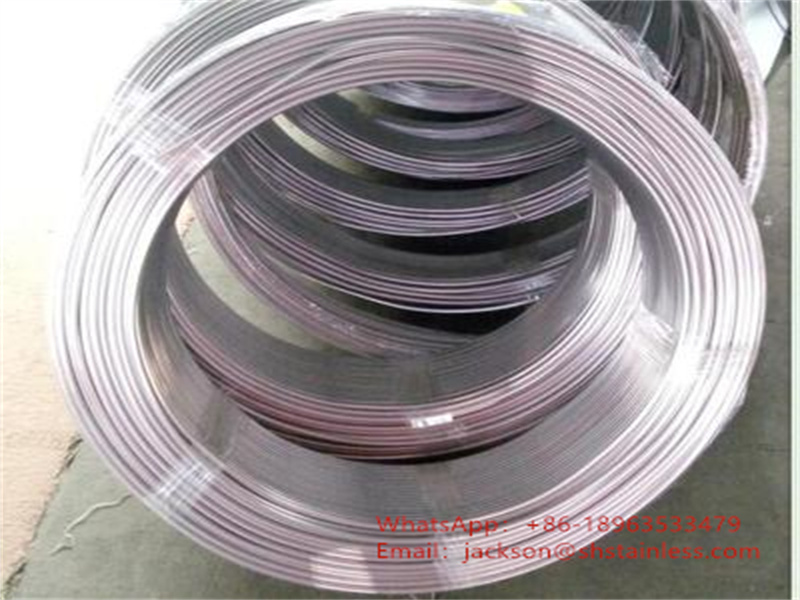

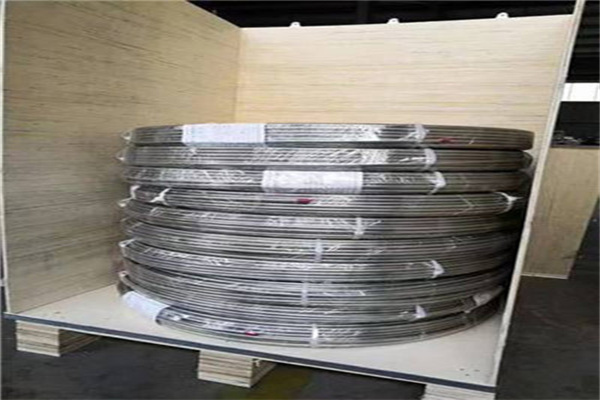

904L Stainless Steel Tubing is makke fan in net-stabilisearre austenitysk roestfrij stiel dat leech is yn koalstofynhâld.De legere koalstof ynhâld makket it mooglik foar maklik welding sûnder folle carbid delslach by welding.Pearl Overseas is in fabrikant en leveransier fan Ss 904l Tubing yn ferskate noarmen, soarten en foarmen.De buizen fariearje yn diameter neffens ferskate noarmen, mar se binne allegear sterker mei 490Mpa treksterkte en 220MPa opbringststerkte.Alle 904l RVS Tubing is hege temperatuer resistint en kin operearje ûnder ferhege temperatuer.De materiaal gearstalling hat chromium, nikkel en molybdeen yn it en as gefolch, it materiaal hat in heech smeltpunt by 1350 graden Celsius en hege corrosie ferset tsjin chloride ion pitting oanfal.De buizen wurde makke of seamless of laske.

De seamless 904l buizen wurde lutsen út in inkele billet fan it materiaal, sadat it oerflak is folle soepeler as de 904L stainless stiel welded buizen.De laske buizen wurde makke fan strips fan 904L materiaal troch longitudinaal of spiraallassen.De 904l RVS buis wurdt brûkt yn hege temperatuer en hege corrosive applikaasjes lykas waarmte Exchangers, kearnsintrales, see wetter desalination planten, marine applikaasjes, iten ferwurkjen en yn gemyske ferwurkjen yndustry.Nim dan kontakt mei ús op foar jo oanpaste oarders of foar fierdere produktfragen.

SS 904L Round Tube Standert Quality Specification

| Spesifikaasjes | ASTM B/ASME SB674 / SB677 |

|---|---|

| Ofmjittings | ASTM, ASME en API |

| SS 904L Tubes Grutte | 1/8 "NB TO 30" NB IN |

| Dikte | 0,35 mm oant 6,35 mm OD yn dikte fariearjend fan 0,1 mm oant 1,2 mm. |

| Skema | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Type | Seamless / ERW / laske / fabrisearre / LSAW buizen |

| Foarm | Rûn, fjouwerkant, rjochthoekich, hydraulysk ensfh |

| Lingte | Single Random, Double Random & Cut Length. |

| Ein | Plain End, Beveled End, Treaded |

Wy leverje hege kwaliteit ASTM B674 TP 904L roestfrij stiel rûne buizen, 904L SS fjouwerkante buis en 904l roestfrij stiel buizen alle maten

904L Stainless Steel Tube Chemical Kompatibilität

| Klasse | C | Mn | Si | P | S | Cr | MO | Ni | Cu | |

|---|---|---|---|---|---|---|---|---|---|---|

| 904L | min. | - | - | - | - | - | 19.0 | 4,0-5,0 | 23.0 | 1.0 |

| max. | 0.20 | 2.0 | 1.0 | 0.045 | 0.035 | 23.0 | 28.0 | 2.0 | ||

Mechanical Strength Table foar AISI SS TP 904L Tubing

| Klasse | Treksterkte (MPa) min | Yield Strength 0,2% Bewiis (MPa) min | Ferlinging (% yn 50 mm) min | Hurdens | |

|---|---|---|---|---|---|

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 446 | 490 | 220 | 35 | 70-90 typysk | - |

Oft jo op syk binne nei SS UNS N08904 Round Tube, 904L Stainless Steel Dekorative Tube leveransiers yn Sina sille helpe jo fine SS WERKSTOFF NR.1.4539 Rjochthoekige buizen oan geweldige priis.

| Klasse | Tichtheid (kg/m3) | Elastyske modulus (GPa) | Gemiddelde koëffisjint fan termyske útwreiding (m/m/0C) | Thermyske konduktiviteit (W/mK) | Spesifike waarmte 0-1000C (J/kg.K) | Elektryske wjerstân (nm) | |||

|---|---|---|---|---|---|---|---|---|---|

| 0-1000C | 0-3150C | 0-5380C | op 1000 C | op 5000 C | |||||

| 904L | 7500 | 200 | 15.00 | - | - | 13 | - | 500 | 850 |

Materiaal lykweardich fan SS 904L Square Tubes

| STANDERT | WERKSTOFF NR. | UNS | JIS | BS | KS | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 904L | 1.4539 | N08904 | SUS 904L | 904S13 | STS 317J5L | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 |

Meast ferneamde soarten SS 904L Poalske buizen

It folsleine oanbod as omfang fan SS 904L Square Tubes, ASTM B674 TP 904L RVS Bright Annealing Tube, SS 904L Poalske Tube en Tube Inox 904l, krije no in Live Quote

904L SS Bright Annealing Tube Grutte Chart

| Muorre | Grutte (OD) |

|---|---|

| .010 | 1/16″, 1/8″, 3/16″ |

| .020 | 1/16″, 1/8″, 3/16″, 1/4″, 5/16″, 3/8″ |

| .012 | 1/8" |

| .016 | 1/8", 3/16" |

| .028 | 1/8″, 3/16″, 1/4″, 5/16″, 3/8″, 1/2″, 3/4″, 1″, 1 1/2″, 2″ |

| .035 | 1/8″, 3/16″, 1/4″, 5/16″, 3/8″, 7/16″, 1/2″, 16″, 5/8″, 3/4″, 7/ 8″, 1″, 1 1/4″, 1 1/2″, 1 5/8″, 2″, 2 1/4″ |

| .049 | 3/16″, 1/4″, 5/16″, 3/8″, 1/2″, 16″, 5/8″, 3/4″, 7/8″, 1″, 1 1/8 ″, 1 1/4″, 1 1/2″, 1 5/8″, 2″, 2 1/4″ |

| .065 | 1/4″, 5/16″, 3/8″, 1/2″, 16″, 5/8″, 3/4″, 7/8″, 1″, 1 1/4″, 1 1/ 2″, 1 5/8″, 1 3/4″, 2″, 2 1/2″, 3″ |

| .083 | 1/4″, 3/8″, 1/2″, 5/8″, 3/4″, 7/8″, 1″, 1 1/4″, 1 1/2″, 1 5/8″ , 1 7/8″, 2″, 2 1/2″, 3″ |

| .095 | 1/2″, 5/8″, 1″, 1 1/4″, 1 1/2″, 2″ |

| .109 | 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, 2″ |

| .120 | 1/2″, 5/8″, 3/4″, 7/8″, 1″, 1 1/4″, 1 1/2″, 2″, 2 1/4″, 2 1/2″, 3" |

| .125 | 3/4″, 1″, 1 1/4″, 1 1/2″, 2″, 3″, 3 1/4″ |

| .134 | 1" |

| .250 | 3" |

| .375 | 3 1/2" |

| Soarten Seamless 904l Tube | Out diameter (OD) | dikte fan de muorre | Lingte |

|---|---|---|---|

| NB Maten (op foarried) | 1/8" ~ 8" | SCH 5 / SCH 10 / SCH 40 / SCH 80 / SCH 160 | Oant 6 meter |

| Seamless 904l seamless tube (oanpaste maten) | 5.0mm ~ 203.2mm | As per eask | Oant 6 meter |

| Naadleaze 904l laske buis (op foarried + oanpaste maten) | 5.0mm ~ 1219.2mm | 1,0 ~ 15,0 mm | Oant 6 meter |

Stainless Steel Tp 904l Naadleaze buizen bûten Diameter & Tolerânsje

| Nominaal Piip Grutte (inch) | Bûten Diameter | Skema | ||||||||

| 5S | 10S | 40S | 80S | |||||||

| (mm) | (inch) | Wall Dikte en Gewicht | ||||||||

| mm (yn) | kg/m | mm (yn) | kg/m | mm (yn) | kg/m | mm (yn) | kg/m | |||

| 1/8 | 10.3 | 0.405 | - | - | 1.25 (0.049) | 0.28 | 1.73 (0.068) | 0.37 | 2.42 (0.095) | 0.47 |

| 1/4 | 13.7 | 0.540 | - | - | 1.66 (0.065) | 0.49 | 2.24 (0.088) | 0.63 | 3.03 (0.119) | 0,80 |

| 3/8 | 17.2 | 0.675 | - | - | 1.66 (0.065) | 0.63 | 2.32 (0.091) | 0,85 | 3.20 (0.126) | 1.10 |

| 1/2 | 21.3 | 0.840 | 1.65 (0.065) | 0.81 | 2.11 (0.083) | 1.00 | 2.77 (0.109) | 1.27 | 3.74 (0.147) | 1.62 |

| 3/4 | 26.7 | 1.050 | 1.65 (0.065) | 1.02 | 2.11 (0.083) | 1.28 | 2.87 (0.113) | 1.68 | 3.92 (0.154) | 2.20 |

| 1 | 33.4 | 1.315 | 1.65 (0.065) | 1.30 | 2.77 (0.109) | 2.09 | 3.38 (0.133) | 2,50 | 4.55 (0.179) | 3.24 |

| 1 1/4 | 42.2 | 1.660 | 1.65 (0.065) | 1.66 | 2.77 (0.109) | 2.69 | 3.56 (0.140) | 3.39 | 4.86 (0.191) | 4.47 |

| 1 1/2 | 48,3 | 1.900 | 1.65 (0.065) | 1.91 | 2.77 (0.109) | 3.11 | 3.69 (0.145) | 4.06 | 5.08 (0.200) | 5.41 |

| 2 | 60,3 | 2.375 | 1.65 (0.065) | 2.40 | 2.77 (0.109) | 3.93 | 3.92 (0.154) | 5.45 | 5.54 (0.218) | 7.49 |

| 2 1/2 | 73,0 | 2.875 | 2.11 (0.083) | 3.69 | 3.05 (0.120) | 5.26 | 5.16 (0.203) | 8.64 | 7.01 (0.276) | 11.4 |

| 3 | 88,9 | 3.500 | 2.11 (0.083) | 4.52 | 3.05 (0.120) | 6.46 | 5.49 (0.216) | 11.3 | 7.62 (0.300) | 15.3 |

| 3 1/2 | 101.6 | 4.000 | 2.11 (0.083) | 5.18 | 3.05 (0.120) | 7.41 | 5.74 (0.226) | 13.6 | 8.08 (0.318) | 18.6 |

| 4 | 114.3 | 4.500 | 2.11 (0.083) | 5.84 | 3.05 (0.120) | 8.37 | 6.02 (0.237) | 16.1 | 8.56 (0.337) | 22.3 |

| 5 | 141.3 | 5.563 | 2.77 (0.109) | 9.46 | 3.41 (0.134) | 11.6 | 6.56 (0.258) | 21.8 | 9.53 (0.375) | 31.0 |

| 6 | 168,3 | 6.625 | 2.77 (0.109) | 11.3 | 3.41 (0.134) | 13.9 | 7.12 (0.280) | 28.3 | 10.98 (0.432) | 42.6 |

| 8 | 219.1 | 8.625 | 2.77 (0.109) | 14.8 | 3.76 (0.148) | 20.0 | 8.18 (0.322) | 42.5 | 12.70 (0.500) | 64,6 |

| 10 | 273.1 | 10.750 | 3.41 (0.134) | 22.7 | 4.20 (0.165) | 27.8 | 9.28 (0.365) | 60,4 | 12.70 (0.500) | 81,5 |

| 12 | 323,9 | 12.750 | 3.97 (0.156) | 31.3 | 4.58 (0.180) | 36.1 | 9.53 (0.375) | 73,9 | 12.70 (0.500) | 97.4 |

ASTM B674 Tp 904l Stainless Steel Tube Materiaal Testing

- Hardness Test

- Mechanyske testen lykas Tensile of Area

- Posityf materiaalidentifikaasje - PMI-testen

- Gemyske analyze - Spectro Analysis

- Mikro en MacroTest

- Intergranular Corrosion (IGC) Test

- Flaring Test

- Flatten test

- Pitting Resistance Test

Stainless Steel 904l Welded Tubing Melting Range

| 2372–2534°F | 1300–1390°C |

SS 904l Tubing Mean Coefficient of Thermal Expansion

| Temperatuerberik | |||

|---|---|---|---|

| °F | °C | yn/in/°F | cm/cm/°C |

| 68–212 | 20–100 | 8,5 x 10-6 | 15,3 x 10-6 |

Stainless Steel Werkstoff Nr.1.4539 Tubes Skaaimerken

| Temperatuer berik: | Tichte kg/dm³ | Hardheid (HB) |

|---|---|---|

| druk bom / druk tank – 60°C oant 400°C | 7, 9 | ≤ 230 |

ASTM B677 Tp 904l SS Seamless Tubes Alternative Grades

| Klasse | Skaaimerken fan alternative graden fan SS 904L |

|---|---|

| 316L | In legere kosten alternatyf, mar mei folle legere corrosie ferset. |

| 6 Mo | In hegere wjerstân tsjin pitting en spaltkorrosje is nedich. |

| 2205 | In heul ferlykbere korrosjebestriding, mei de 2205 mei hegere meganyske sterkte, en tsjin in legere kosten oant 904L.(2205 net geskikt foar temperatueren boppe 300 ° C.) |

| Super duplex | Hegere korrosjebestriding is nedich, tegearre mei in hegere sterkte dan 904 |

SS 904L Santiary Tube Heat Resistance

| Materiaal | Temperatuer |

| Hege druk seamless 904l buizen | 400°C |

SS 904L Cold Rolled Coiled Tubing Heat Treatment

| Materiaal | Heat-behannele |

| 904L roestfrij stiel naadleaze buizen | 1090 oant 1175 °C |

SS 904L Poalsk Tube Grutte Range

| SIZE RANGE | |

| Buitendiameter (OD) | Dikte fan de muorre |

| 1/4" - 1" | .035" - .065" |

SS TP904L Seamless Tubing Teoretyske Burst Pressure

| OD | MUORRE | ID | PSI |

| 0.250 | 0.035 | 0.180 | 16.898 |

| 0.250 | 0.049 | 0.152 | 23.657 |

| 0.250 | 0.065 | 0.120 | 31.382 |

| 0.375 | 0.035 | 0.305 | 11.265 |

| 0.375 | 0.049 | 0.277 | 15.771 |

| 0.500 | 0.035 | 0.430 | 8.946 |

| 0.500 | 0.049 | 0.402 | 12.524 |

| 0.500 | 0.065 | 0.370 | 16.614 |

| 0.750 | 0.065 | 0.620 | 11.076 |

| 1.000 | 0.065 | 0.870 | 8.307 |

SS UNS N08904 Heat Exchanger Tube Dimensional Tolerances

| BUITEN DIAMETER (OD) | OD TOLERANSJE | WALL TOLERANCE | |

| TOT 1/2" | +/- .005" | +/- 15% | |

| 1/2 ″ oant 1-1/2 ″ EXCL. | +/- .005" | +/- 10% | |

Ynventarisaasje fan SS 904L Tubing

Kontrolearje dus foar lêste updates yn ASTM B674 TP 904L RVS rjochthoekige buis, naadleaze 904l buizen, Ss 904l buizen en 904l buizendrukwurdearring dy't jo wolle keapje

| SS 904L Tubing | Stainless Steel 904L hege druk buis |

| RVS 904L buizen | Stainless Steel 904L Welded Tube |

| WNR 1.4539 Tubing | SS 904L Rjochthoekige buizen |

| UNS N08904 Tubing | SS 904L Rûne buizen |

| AISI 904L Tubing | 904L SS Seamless Tube |

| SUS 904L Tubing | UNS N08904 Naadleaze Tube |

| INOX 904L Tubing | WERKSTOFF NR.1.4539 Naadleaze buizen |

| Alloy 904L Tubing | ASME SB677 TP 904L Stainless Steel Seamless Tube |

| 904L RVS buizen | SS 904L laske buizen |

| hege kwaliteit SS 904L Tubing | 904L SS laske buis |

| Stainless Steel 904L Square Tubing | 904L Stainless Steel laske buizen |

| Stainless Steel 904L Coiled Tubing | SS UNS N08904 Welded Tube |

| 904L Stainless Steel Instrumentation Tubing | SS WERKSTOFF NR.1.4539 laske buizen |

| SS 904L Seamless Tubing | ASTM B674 TP 904L Stainless Steel laske buizen |

| SS 904L Rjochthoekige Tubing | SS 904L Rûne Tube |

| 904L Stainless Steel Bright Annealed Tubing | 904L SS Rûne buizen |

| 904L Stainless Steel Welded Tubing | 904L RVS Rûne Tube |

| 904L Stainless Steel Electropolished Tubing | UNS N08904 Rûne buizen |

| RVS 904L rjochthoekige buizen | SS UNS N08904 Round Tube |

| SS 904L EFW Tubing | ASTM B674 TP 904L Rûne stiel rûne buizen |

| 904L RVS ERW Tubing | SS 904L fjouwerkante buizen |

| 904L Stainless Steel Square Tubing | 904L SS Square Tube |

| Stainless Steel 904L Coiled Seamless Tubing | 904L Stainless Steel Square Tubes |

| 904L RVS Round Tubing | UNS N08904 Square Tube |

| WNR 1.4539 RVS buizen coil | WERKSTOFF NR.1.4539 fjouwerkante buizen |

| AISI 904L roestfrij stiel buizen | ASME SB677 TP 904L Stainless Steel Square Tube |

| SUS 904L Small Diameter Tubing | 904L SS Rjochthoekige Tube |

| INOX 904L laske en lutsen buizen | 904L RVS rjochthoekige buizen |

| Alloy 904L Square Tubing | SS UNS N08904 Rjochthoekige Tube |

| 904L Stainless Steel Hydraulic Tubing | SS WERKSTOFF NR.1.4539 Rjochthoekige buizen |

| SAE 904L Hypodermic Tubing | ASTM B674 TP 904L RVS rjochthoekige buis |

| naadleaze roestfrij stiel buizen | SS 904L Dekorative Tube |

| Stainless Steel TP 904L Tubing | 904L SS dekorative buizen |

| Stainless Steel TP 904L Naadleaze buizen | 904L Stainless Steel Dekorative Tube |

| ASTM B677 TP 904L SS Naadleaze buizen | SS UNS N08904 Dekorative buizen |

| Stainless Steel 904L Cold Drawn buizen | SS WERKSTOFF NR.1.4539 Dekorative Tube |

| Stainless Steel DIN 1.4539 Naadleaze buizen | ASTM B677 TP 904L Stainless Steel dekorative buizen |

| SS UNS N08904 Seamless Tubing | SS 904L Sanitêre Tube |

| SS 904L Cold Drawn Tubes | 904L SS sanitêre buizen |

| SS 904L Naadleaze buizen | 904L Stainless Steel Sanitêre Tube |

| Stainless Steel 904L Naadleaze buizen | SS UNS N08904 Sanitêre buizen |

| SS TP 904L Naadleaze buizen | SS WERKSTOFF NR.1.4539 Sanitêre Tube |

| Stainless Steel 904L ubes | ASTM B674 TP 904L RVS sanitêre buizen |

| SS 904L buizen | SS 904L Poalske buizen |

| ASTM B 677 Stainless Steel 904L Naadleaze buizen | 904L SS Poalske Tube |

| SS TP 904L Cold Drawn Tubes | 904L Stainless Steel Poalske buizen |

| AISI SS TP 904L Tubing | SS UNSN08904 Poalske Tube |

| Stainless Steel 904L Naadleaze Tubing | SS WERKSTOFF NR.1.4539 Poalske buizen |

| DIN 1.4539 Stainless Steel 904L Naadleaze buizen | ASTM B674 TP 904L Stainless Steel Poalske Tube |

| RVS 904L Tube | SS 904L Instrumentation Tube |

| SS UNS N08904 Heat exchager Tube | 904L SS Instrumentation Tubes |

| 904L roestfrij stiel naadleaze buizen | 904L Stainless Steel Instrumentation Tube |

| RVS WERKSTOFF NR.1.4539 Tubes | SS UNS N08904 Instrumentation Tubes |

| 904L SS Dekorative Tube | SS WERKSTOFF NR.1.4539 Instrumentation Tube |

| ASTM B677 RVS buizen | ASTM B677 TP904L Stainless Steel Instrumentation Tubes |

| Stainless Steel 904L Instrumentation Tubes | 904L Stainless Steel Heat Exchanger Tubes |

| SS 904L Santiary Tube | SS UNS N08904 Heat Exchanger Tube |

| RVS DIN 1.4539 | SS WERKSTOFF NR.1.4539 Heat Exchanger Tubes |

| ASTM B674 TP 904L RVS hege druk Tube | ASTM B677 TP 904L Stainless Steel Heat Exchanger Tubes |

| SS 904L Kâldrôle Coiled Tubing | SS 904L Bright Annealing Tubes |

| SS 904L waarmte-útwikseler Tube | 904L SS Bright Annealing Tube |

| ASTM B674 TP 904L Stainless Steel Tube | 904L Stainless Steel Bright Annealing Tubes |

| Stainless Steel 904L Welded buizen | SS UNS N08904 Bright Annealing Tube |

| SS 904L Poalske Tube | SS WERKSTOFF NR.1.4539 Bright Annealing Tube |

| SS TP904L Seamless Tubing | ASTM B674 TP 904L Stainless Steel Bright Annealing Tube |

| TP904L SS laske buizen | Tube Inox 904l |

| SS 904L Electropolish Tube | 904l RVS Tube |

| Stainless Steel 904L Bright Annealed Tube | Naadleaze 904l buizen |