Kâld rôle 316L RVS coil roll út Sina

316 Stainless Steel Coils Definysje

Kâld rôle 316L RVS coil roll út Sina

Grade 316 Stainless Steel is de standert molybdenum-dragende klasse, twadde yn belang nei 304 ûnder de austenityske roestfrij stielen.It molybdenum jout 316 bettere algemiene korrosjebestindige eigenskippen dan Grade 304, benammen hegere ferset tsjin pitting en spaltkorrosje yn chloride-omjouwings.It hat poerbêste foarmjen en welding eigenskippen.It is maklik rem of roll foarme yn in ferskaat oan dielen foar tapassingen yn de yndustriële, arsjitektoanyske, en ferfier fjilden.Grade 316 hat ek treflike welding skaaimerken.Post-weld annealing is net nedich by welding tinne seksjes.

Grade 316L, de lege koalstof ferzje fan 316 en is ymmún fan sensibilisaasje (nôt grins carbid delslach).Sa wurdt it wiidweidich brûkt yn swiere gauge laske komponinten (oer sawat 6 mm).Grade 316H, mei syn hegere koalstofynhâld hat tapassing by ferhege temperatueren, lykas stabilisearre klasse 316Ti.

De austenityske struktuer jout dizze klassen ek poerbêste taaiens, sels oant kryogenyske temperatueren

It is de foarkar stiel foar gebrûk yn marine omjouwings fanwege syn gruttere wjerstân tsjin pitting corrosie dan oare graden fan stiel.It feit dat it negligibly reageart op magnetyske fjilden betsjut dat it kin wurde brûkt yn tapassingen wêr't in net-magnetysk metaal fereaske is.Njonken molybdeen befettet 316 ek in oantal oare eleminten yn wikseljende konsintraasjes.Lykas oare graden fan roestfrij stiel, is roestfrij stiel fan marine grade in relatyf minne dirigint fan sawol waarmte as elektrisiteit yn ferliking mei metalen en oare conductive materialen.

Wylst 316 net folslein rustbestindich is, is de alloy mear korrosjebestindich as oare gewoane roestfrij stielen.Chirurgysk stiel is makke fan subtypen fan 316 roestfrij stiel.

316 Stainless Steel Coil Range

| 316 Stainless Steel Coil Spesifikaasje | ASTM A240 / ASME SA240 |

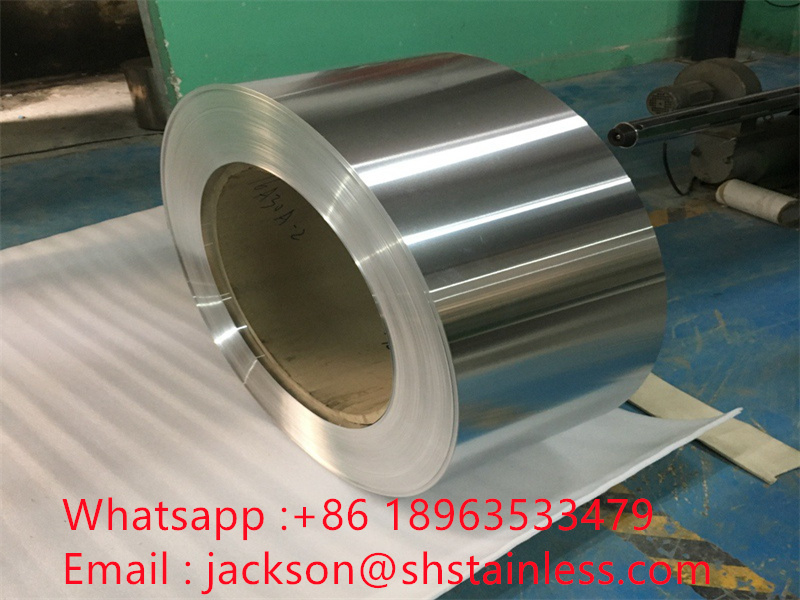

| 316 Stainless Steel Coil Manufacturing Process | Warm rôle (HR) / Kâld rôle (CR) |

| 316 Stainless Steel Coil Graden | 202 / 304 / 304L / 304H / 309S / 310S / 316 / 316L / 316Ti / 317L / 321 / 321H / 347 / 347H / 904L ensfh. UNS No. – UNS S30400, UNS S30403, UNS S31008, UNS S31620, UNS S31603, UNS S31603, UNS S31635, UNS S31703, UNS S32100, UNS S34700, UNS S34700, UNS90, S34700, UNS90, S31603 EN No. – 1.4301, 1.4307, 1.4845, 1.4401, 1.4404, 1.4571, 1.4438, 1.4541, 1.4550, 1.4551, 1.4539 |

| 316 Stainless Steel Coil Dikte | 0,6 MM TO 80 MM DIKKE |

| 316 Stainless Steel Coil Breedte | 1250 MM / 1500 MM / 2000 MM / 04 Feet / 05 Feet en oanpaste snijbreedte as per eask |

| 316 Stainless Steel Coil Length | 2400 MM / 2420 MM / 6000 MM / 08 Feet / 10 Feet / Coil Cut and Custom Cut Length as Per Requirement |

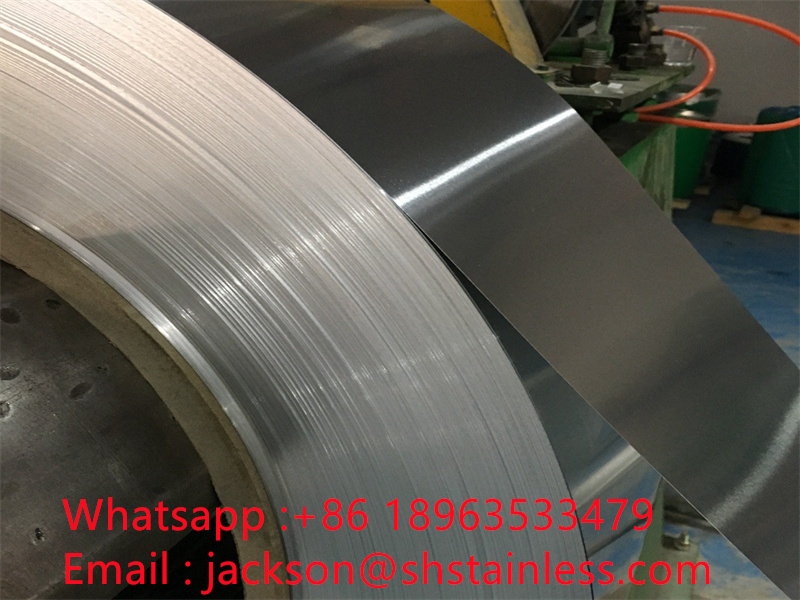

| 316 Stainless Steel Coil Surface Finish | 2B, 2D, BA, MATT, MATT PVC, No.4, No.5, SB, HR, No.8, Mirror, Hairline, Borstel, Textured, Oaljebasis wiet Polished, Beide kanten Polished beskikber. |

| 316 Stainless Steel Coil Coating | PVC coating Normaal / Laser, Film: 100 mikrometer, Kleur: swart / wyt. |

| 316 Stainless Steel Coil Oare Testing | NACE MR0175, Ultrasoung TEST, IGC TEST, Intergranular Corrrosion Test as per ASTM A262 Practice E, Charpy Impact Test, Macro, Grain Size, Hardness, ensfh. |

| 316 Stainless Steel Coil Wearde Added Services | Gas Cutting / CNC Plasma Cutting / Profiling / Rolling / Bending / Coil Metal Fabrication / Drill / Punch / Machtigingsformulier / Sand Blasting / Shot Blasting / Heat Treatment |

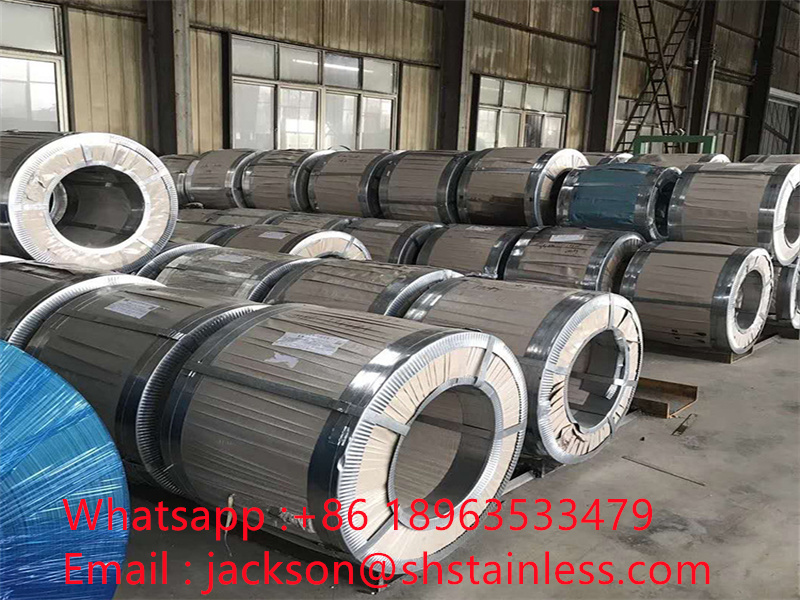

| 316 Stainless Steel Coil Packaging | Los / Carrate / Houten Pallet / Houten doaze-a / Plastic Cloth Wraps |

| 316 Stainless Steel Coil Shipment & Transportation | By Road - Frachtwein / Trein Diellading, Folsleine Load, By See - Break-bulk Konvinsjoneel skip / FCL (folsleine kontenerlading) / LCL (minder kontenerlading) / 20 feet kontener / 40 feet kontener / 45 feet kontener / kontener mei hege kubus / Open Top Container, By Air - Frachtskip Civil Passenger and Cargo Planes |

| 316 Stainless Steel Coil Materiaal Test Sertifikaat | Fabrikant Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab./ Under Third Party Inspection Agency Lykas SGS, TUV, DNV, LLOYDS, ABS, Bureau of Indian Standards BIS Approved ETC |

316 Stainless Steel Coil gemyske komposysje en eigenskippen

De gemyske gearstalling fan klasse 316 Stainless Steel wurdt sketst yn de folgjende tabel

| Klasse | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 316 | Min | - | - | - | 0 | - | 16.0 | 2.00 | 10.0 | - |

| Max | 0.08 | 2.0 | 0,75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | 0.10 | |

| 316L | Min | - | - | - | - | - | 16.0 | 2.00 | 10.0 | - |

| Max | 0.03 | 2.0 | 0,75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | 0.10 | |

| 316H | Min | 0.04 | 0.04 | 0 | - | - | 16.0 | 2.00 | 10.0 | - |

| max | 0.10 | 0.10 | 0,75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | - |

316 Stainless Steel Coil meganyske en fysike eigenskippen

De meganyske eigenskippen fan klasse 316RVS Coilswurde werjûn yn 'e folgjende tabel.

| Klasse | Tensile Str (MPa) min | Yield Str 0,2% Bewiis (MPa) min | Elong (% yn 50 mm) min | Hurdens | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 316 | 515 | 205 | 40 | 95 | 217 |

| 316L | 485 | 170 | 40 | 95 | 217 |

| 316H | 515 | 205 | 40 | 95 | 217 |

316 STAINLESS STEEL COILS FYSISKE EIGENSCHAPPEN

Fysike eigenskippen fan 316 grade RVS yn de annealed tastân

| Klasse | Tichtheid (kg/m3) | Elastyske modulus (GPa) | Gemiddelde ko-eff fan termyske útwreiding (µm/m/°C) | Warmtegelieding (W/mK) | Spesifike Heat 0-100 ° C (J/kg.K) | Elec Resistivity (nΩ.m) | |||

| 0-100°C | 0-315°C | 0-538°C | Op 100°C | Op 500°C | |||||

| 316/L/H | 8000 | 193 | 15.9 | 16.2 | 17.5 | 16.3 | 21.5 | 500 | 740 |

316 Stainless Steel Coil Beskikber Oare Grade

Mooglike alternative graden foar 316 grade roestfrij stiel

| EN-standard Staal nr.khs DIN | EN-standard Stiel namme | SAE klasse | UNS |

| 1.4109 | X65CrMo14 | 440A | S44002 |

| 1.4112 | X90CrMoV18 | 440B | S44003 |

| 1.4125 | X105CrMo17 | 440C | S44004 |

| 440F | S44020 | ||

| 1.4016 | X6Cr17 | 430 | S43000 |

| 1.4408 | GX 6 CrNiMo 18-10 | 316 | S31600 |

| 1.4512 | X6CrTi12 | 409 | S40900 |

| 410 | S41000 | ||

| 1.4310 | X10CrNi18-8 | 301 | S30100 |

| 1.4318 | X2CrNiN18-7 | 301LN | |

| 1.4307 | X2CrNi18-9 | 304L | S3043 |

| 1.4306 | X2CrNi19-11 | 304L | S30403 |

| 1.4311 | X2CrNiN18-10 | 304LN | S30453 |

| 1.4301 | X5CrNi18-10 | 304 | S30400 |

| 1.4948 | X6CrNi18-11 | 304H | S30409 |

| 1.4303 | X5CrNi18-12 | 305 | S30500 |

| X5CrNi30-9 | 312 | ||

| 1.4841 | X22CrNi2520 | 310 | S31000 |

| 1.4845 | X 5 CrNi 2520 | 310S | S31008 |

| 1.4541 | X6CrNiTi18-10 | 321 | S32100 |

| 1.4878 | X12CrNiTi18-9 | 321H | S32109 |

| 1.4404 | X2CrNiMo17-12-2 | 316L | S31603 |

| 1.4401 | X5CrNiMo17-12-2 | 316 | S31600 |

| 1.4406 | X2CrNiMoN17-12-2 | 316LN | S31653 |

| 1.4432 | X2CrNiMo17-12-3 | 316L | S31603 |

| 1.4435 | X2CrNiMo18-14-3 | 316L | S31603 |

| 1.4436 | X3CrNiMo17-13-3 | 316 | S31600 |

| 1.4571 | X6CrNiMoTi17-12-2 | 316Ti | S31635 |

| 1.4429 | X2CrNiMoN17-13-3 | 316LN | S31653 |

| 1.4438 | X2CrNiMo18-15-4 | 317L | S31703 |

| 1.4362 | X2CrNi23-4 | 2304 | S32304 |

| 1.4462 | X2CrNiMoN22-5-3 | 2205 | S31803/S32205 |

| 1.4501 | X2CrNiMoCuWN25-7-4 | J405 | S32760 |

| 1.4539 | X1NiCrMoCu25-20-5 | 904L | N08904 |

| 1.4529 | X1NiCrMoCuN25-20-7 | N08926 | |

| 1.4547 | X1CrNiMoCuN20-18-7 | 254SMO | S31254 |